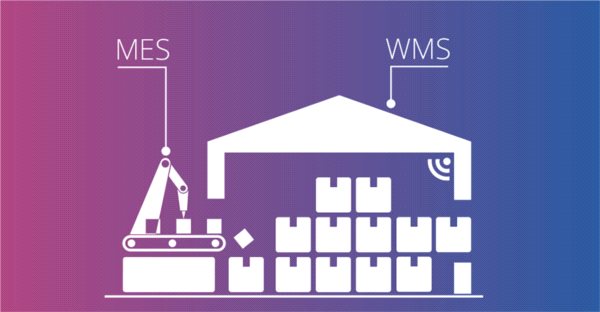

Factory 4.0 – Integration of production and storage systems

The condition for good cooperation between these two departments is to ensure quick and precise exchange of key information. This means the need to synchronize IT systems that support warehouse and production. On what planes and for what purpose integration of MES (Manufacturing Execution System) production systems and WMS (Warehouse Management System) can take place

Areas of integration

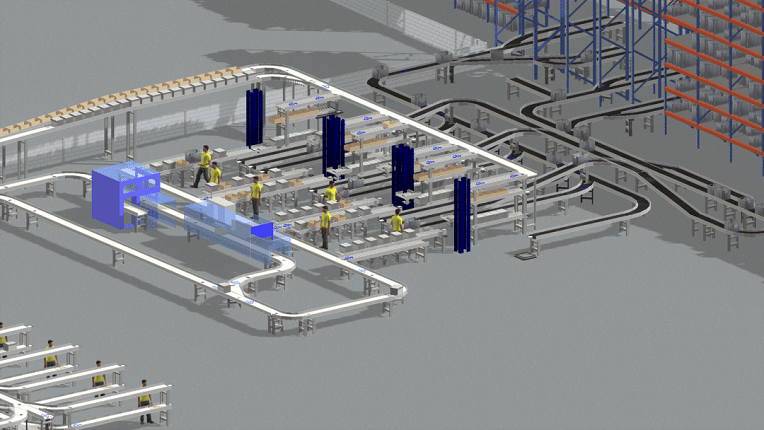

One of the goals of MES and WMS software integration is to improve the supply of materials and components to production stations. Due to the fact that the MES system manages the flow of materials in real time, it is possible to supply individual positions on an ongoing basis from the warehouse, without the need for excessive storage of inventory at the production sockets.

The integration of MES and WMS systems facilitates the handling of material instructions (BOM – Bill of Materials). If a new production order is placed in the MES system, the warehouse program will automatically reserve the materials needed for its implementation, and in the absence of them, replacements defined in the system. Fast flow of information between MES and WMS systems allows better planning and controlling inventory levels.

The cooperation of the WMS system and the MES software also means better control over the materials migrating between the warehouse and the production hall. In practice, we often encounter the situation that components downloaded from the warehouse return to it if they are not used. Without the integration of the MES system with the storage system, it is difficult to obtain reliable information on the current status of individual components.

The integration of production and warehouse management systems provides the enterprise with complete information on the flow of raw materials through the production hall and the warehouse. This is the starting point for efficient improvement of the enterprise value stream. Insight into the flow of materials, semi-finished and finished products helps eliminate waste resulting from downtime, unnecessary activities or inadequate inventory.